|

It’s a Cheesy Business

By Matt J. Stender

What is something that none of us on earth can live without? I know there will be a plethora1 of answers to such a question.

“I can’t live without my mobile telephone, without my computer and internet, my mp3 player....” The list of “necessities” is endless. But, just stop to think, we truly can live without these conveniences. Yet, food, water and shelter are indispensable.

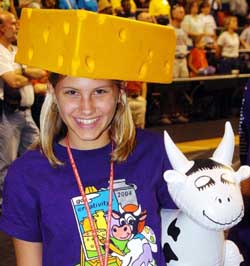

Take food for example. The next time you sink your teeth into a chunk of cheese ponder the journey it has taken. Work has to be done by literally hundreds of people to afford us just a small pleasure and necessity. Many of us never give such items a second thought2. But, being from Wisconsin, the Dairy State, home of the Cheese Head, I would like to take you with me as we follow a brick of cheese from producer to consumer. Who is involved in the process, the complexities, marketing strategies, production, transportation and sales?

Take food for example. The next time you sink your teeth into a chunk of cheese ponder the journey it has taken. Work has to be done by literally hundreds of people to afford us just a small pleasure and necessity. Many of us never give such items a second thought2. But, being from Wisconsin, the Dairy State, home of the Cheese Head, I would like to take you with me as we follow a brick of cheese from producer to consumer. Who is involved in the process, the complexities, marketing strategies, production, transportation and sales?

So, as we take a bite of cheese, let us travel back to were it all begins, the initial step in creation. Cheese is a derivative of milk, and in our case, cows milk. In order for the dairy farmer to produce the milk, cows are needed. One of the most common ways to obtain a cow in Wisconsin is to visit a livestock3 auction where the farmer bids4 and purchases milk cows or calves to be raised as milkers.

After spending all day viewing and purchasing cattle the farmer must transport them back to the farm, sometimes hundreds of miles away. The easiest way of accomplishing this is to hire a specialized carrier5, a logistics company6 with special equipment and a knowledge of handling livestock. A tractor-trailer measuring about 72 feet long, a weight of 80,000 pounds and five axles7 is used, the trailer is of a special design with many large vents8 and two levels. Not just any person can operate such a vehicle, one must undergo special training and obtain a commercial driver’s license. Many governmental rules and regulations must be followed regarding hours of service spent driving and working, safety inspections9 of the vehicle, proper permits and licenses for the truck and trailer, payment of taxes and tolls10 and having the correct and legal documents of operation. The driver must also have a bill of lading11 for each load he carries, stating the weight and pieces onboard, the name and addresses of the shipper12 and consignee13.

The cattle make it to14 the farm where they are herded out of the trailer and into pastures or large feed barns15. Obviously, for the cows to produce milk they must eat, and just as we must have a healthy diet so must they. A custom diet is designed for each cow, a mixture of vitamins, grains and grasses are used. Growing the grains and grasses, such as corn and alfalfa16, is a year round project. Each late autumn the ground is turned over with plows17 pulled by large tractors, during the winter months manure18 is spread over the fields as a source of fertilizer19, and as the ground dries in spring it is plowed and disked20, rocks are picked and the fields planted. Other fertilizers and herbicides are applied as the growing season passes, and sometimes the fields need to be irrigated as well. Throughout the summer hay21 is cut and, before the corn has dried, chopped silage22 is prepared. In autumn the dried corn is harvested, all of these are then used to feed the cattle.

The cattle make it to14 the farm where they are herded out of the trailer and into pastures or large feed barns15. Obviously, for the cows to produce milk they must eat, and just as we must have a healthy diet so must they. A custom diet is designed for each cow, a mixture of vitamins, grains and grasses are used. Growing the grains and grasses, such as corn and alfalfa16, is a year round project. Each late autumn the ground is turned over with plows17 pulled by large tractors, during the winter months manure18 is spread over the fields as a source of fertilizer19, and as the ground dries in spring it is plowed and disked20, rocks are picked and the fields planted. Other fertilizers and herbicides are applied as the growing season passes, and sometimes the fields need to be irrigated as well. Throughout the summer hay21 is cut and, before the corn has dried, chopped silage22 is prepared. In autumn the dried corn is harvested, all of these are then used to feed the cattle.

Well fed cows need to be milked, and on large farms this is a never ending endeavor. Modern milking parlors23 are highly automated; the farm hands clean the udders24 and secure the milking device, as opposed to the old method of sitting on a stool and milking by hand into a pail. The milk is stored in large stainless steel holding tanks until a carrier, similar to the one used to transport the cattle, pumps it into a tank trailer and delivers it to the dairy.

All of the money needed to pay for the farmers cows, the cost of transportation, his tractors and implements, seed, fertilizers and herbicides, barns, milking parlors and equipment must be compensated for by the sale of milk to the dairy.

At the dairy the milk is pumped off the truck where professional and licensed cheese makers craft special mixtures of enzymes25 and different ingredients, depending on the type of cheese to be made. Some cheeses are smoked, some aged, some left in curd26 form, wine may be added to others. High standards, such as cleanliness, must be met in the production of cheese, which the government observes very closely.

In Wisconsin, where the cheese industry is very competitive, great lengths are taken to make one cheese stand out from the rest. Market research is compiled and an advertising campaign is undertaken. A group of media illustrators and copywriters create multiple ideas which are pitched27 to the customer, in this case the dairy which has produced the cheese. After an idea is agreed upon by both parties the advertising agency sets out on implementing the program. Packaging products, such as boxes and labels need to be printed, slogans and catch phrases developed, television and radio commercials produced, print media ads pasted up, point of purchase displays created and sent to grocery and convenience stores28.

In Wisconsin, where the cheese industry is very competitive, great lengths are taken to make one cheese stand out from the rest. Market research is compiled and an advertising campaign is undertaken. A group of media illustrators and copywriters create multiple ideas which are pitched27 to the customer, in this case the dairy which has produced the cheese. After an idea is agreed upon by both parties the advertising agency sets out on implementing the program. Packaging products, such as boxes and labels need to be printed, slogans and catch phrases developed, television and radio commercials produced, print media ads pasted up, point of purchase displays created and sent to grocery and convenience stores28.

Printing factories pump out29 labels, paper factories cut and fold boxes, television studios build sets and shoot film, radio personalities narrate script, hundreds of people are involved and many hours spent on developing, in the public, a psychological need for the product.

Back at the dairy, the cheese has been packaged and boxed for shipment30 to the distribution center. Another logistics company is hired to bridge the transportation gap31 encountered here. Once at the grocery warehouse the truck is unloaded and the product sorted by coded numbers, palletized32 and counted. All of this information is entered into the data base and matched to the incoming purchase orders submitted by different stores. Bricks of cheddar, boxes of string cheese33, and jars of red wine cheese are redistributed onto trucks that then deliver to the stores in need.

Store personnel or vendors then stock the shelves and display cases with a wide variety of cheeses that cater to our taste and need.

Some cheeses are not destined to be eaten though. Wisconsinites wear hats made of swiss, carve statues of Elvis from cheddar and fry up one of the worlds largest cheeseburgers.

Now, as we swallow our tasty bit of cheese we can understand just how many steps are encountered along the way. The number of jobs that are created and filled by hundreds of people in many diverse areas of the economy. Not only cheese follows this path, but almost everything eaten in the United States takes a similar journey to the dinner table.

The need for food is not so different from the wants of modern technology and the creation of consumer goods demanded of, by us, the purchasing public.

1 plethora – изобилие

2 second thought – мысль, пришедшая в голову после размышления

3 livestock – крупный рогатый скот

4 bid – принимать участие в торгах

5 carrier – транспортное агентство

6 logistics company – логистическая компания

7 axle – вал

8 vent – вентиляционное отверстие

9 safety inspection – технический осмотр

10 toll – пошлина

11 bill of lading – накладная

12 shipper – грузоотправитель

13 consignee – грузополучатель

14 make it to – (разг.) добраться (до места)

15 feed barn – коровник

16 alfalfa – люцерна

17 plow – (амер.) плуг

18 manure – навоз, компост

19 fertilizer – удобрение

20 disk – обрабатывать дисковым культиватором

21 hay – сено

22 silage – силос

23 milking parlor – доильный зал

24 udder – вымя

25 enzyme – фермент

26 curd – творог

27 pitch – расхваливать свой товар, пытаясь его продать

28 convenience store – удобно расположенный магазин, работающий допоздна (или круглосуточно) и соответствующий местным вкусам

29 pump out – производить в большом количестве

30 shipment – отправка (товаров)

31 bridge the gap – заполнять промежуток

32 palletize – штабелировать (грузы) на поддоне

33 string cheese – белый волокнистый сыр в виде длинных палочек или косичек

Читать еще в этой рубрике:

Читать еще в этом номере:

|

|